China has remained the world’s largest automotive manufacturing country and automotive market since 2009. In 2016, annual vehicle production in China accounted for nearly 30 percent of worldwide vehicle production, which exceeds that of the European Union or that of the United States and Japan combined. In 2019, passenger car production in China is stated at 21.36 million units.

With the quality of domestic Chinese products increasing across all sectors, and with the Chinese industrial robot market in a rapid growth phase, and the world’s largest application market for the last seven years its little wonder that robotic automated metrology, focused on the automotive sector, has received attention from Chinese domestic technology suppliers.

In 2018, around 154,000 industrial robots were installed in China. Chinese robot suppliers increased their share of total installations of the domestic market to 27%. This result being inline with China´s policy to promote domestic manufacturers according to the International Federation of Robotics.

One company IsvisionTechnology Co., Ltd. (ISV), originating out of Tianjin University developments, now has more than 200 employees with facilities in Hangzhou and Tianjin. The company strives to provide customers with complete vision solutions and products for inline geometric dimension measurement system, visual guiding system, glue bead inspection system, blue light scanning system, gap & flush system, and defect detection systems. ISV systems have been applied to automotive, aerospace, aviation, rail transit and other high-end manufacturing fields. ISV has broken the monopoly breaks originally enjoyed by foreign brands and is a supplier to many domestic mainstream vehicle manufacturers, including SAIC-VW, SAIC-GM, and FAW-VW. In the meantime, ISV has established partnerships with CRRC, CSSC, CASC, and AVIC with its cutting-edge measurement technology.

One company IsvisionTechnology Co., Ltd. (ISV), originating out of Tianjin University developments, now has more than 200 employees with facilities in Hangzhou and Tianjin. The company strives to provide customers with complete vision solutions and products for inline geometric dimension measurement system, visual guiding system, glue bead inspection system, blue light scanning system, gap & flush system, and defect detection systems. ISV systems have been applied to automotive, aerospace, aviation, rail transit and other high-end manufacturing fields. ISV has broken the monopoly breaks originally enjoyed by foreign brands and is a supplier to many domestic mainstream vehicle manufacturers, including SAIC-VW, SAIC-GM, and FAW-VW. In the meantime, ISV has established partnerships with CRRC, CSSC, CASC, and AVIC with its cutting-edge measurement technology.

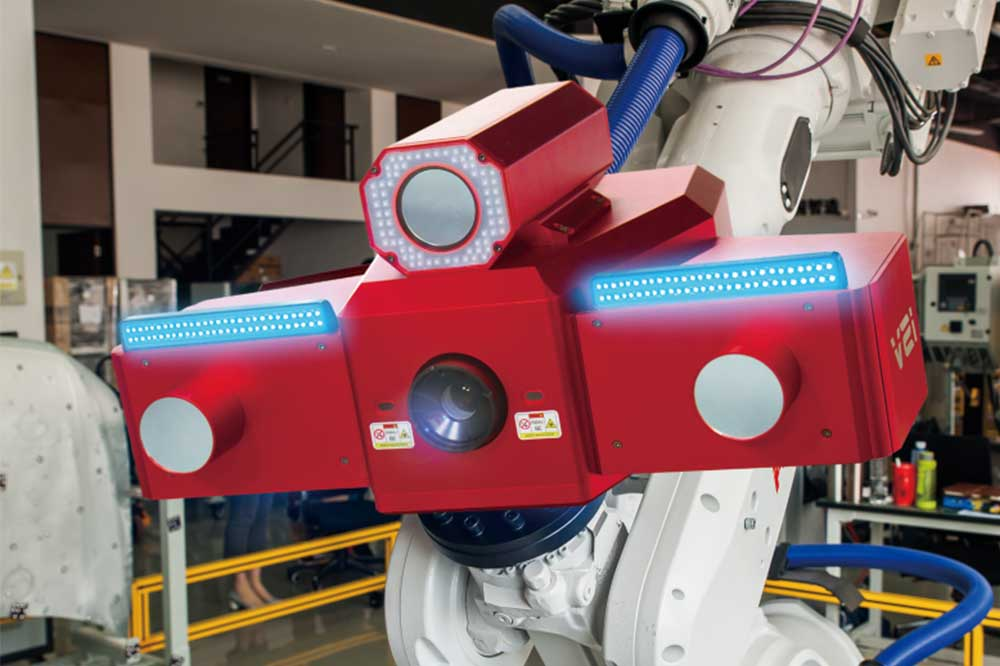

The ISV blue light scanning measurement system acquires point-clouds by means of structured light non-contact optical measurement principle, and realizes large-range flexible measurement with high-density point-cloud measurement mounted to a robot, guide rail or rotary table. The software system can complete the fully-automatic process including trajectory programming, point cloud acquisition, point cloud processing, and the generation of final report. Benefiting from its high efficiency, high precision, large data volume, low cost ISV the blue light scanning measurement system is claimed to be gradually replacing CMM system to become the mainstream tool for the dimensional measurement of components and even complete vehicles in China. Application scope of the ISV system covers measurement of vehicle and components, offline measurement of welded sub-assemblies and measurement of dies in stamping plants.

The ISV blue light scanning measurement system acquires point-clouds by means of structured light non-contact optical measurement principle, and realizes large-range flexible measurement with high-density point-cloud measurement mounted to a robot, guide rail or rotary table. The software system can complete the fully-automatic process including trajectory programming, point cloud acquisition, point cloud processing, and the generation of final report. Benefiting from its high efficiency, high precision, large data volume, low cost ISV the blue light scanning measurement system is claimed to be gradually replacing CMM system to become the mainstream tool for the dimensional measurement of components and even complete vehicles in China. Application scope of the ISV system covers measurement of vehicle and components, offline measurement of welded sub-assemblies and measurement of dies in stamping plants.

ISV gap and flushness measurement systems measures assembled vehicle dimensions with laser technology and machine vision technology.. This system is designed with diversified algorithms in order to adapt to different characteristic surfaces and ensure stable measurement and high precision. The company offers both robotic and handheld gap and flushness measurement solutions, specially developed for assembly dimensions with complicated contours. Acquired high-quality images and data reflect actual gap and flushness objectively by replacing traditional measurement tools integrated with complete data acquisition, storage, transmission and management automatically.

For more information: www.tjisv.com