More power and more speed were the key themes of robot exhibits at the Düsseldorf show in October. “Less” was a contrasting theme: less upfront investment and lower operating costs, less space occupied, less safety guarding required, and less complexity in programming. Some systems were specialized for structural composites, IML, medical pipettes, and single-use coffee capsules. Related news in automation included quick-mold-change (QMC) systems and automated guided vehicles (AGVs).

Boosting performance: Wittmann’s new Sonic series is said to be 60-70% faster than its WX series. Yushin’s new MKA-200S for machines of 1500 tons and larger handles payloads of 66 to 110 lb while operating 10-17% faster than the company’s earlier large robots.

Cartesian Robots Push the Envelope

On the “more” side, Arburg introduced a new size of linear robot, the Multilift V30 for large Allrounder presses (250 to 650 metric tons). It can heft 30 kg (66 lb) and has the following “reach”:

• Horizontal “Z” stroke of 2000 to 5000 mm; speeds up to 2800 mm/sec;

• Vertical “Y” stroke of 1200 to 2000 mm; speeds to 4000 mm/sec;

• Strip “X” stroke of 700 to 900 mm; speeds to 2400 mm/sec.

Pneumatic “C” wrist axis is standard, servo “C” and servo or pneumatic “B” axes optional.

Yushin also went big with its new MKA-2000S servo robot for machines of 1500 tons and larger. It handles loads of 30 to 50 kg (66 to 110 lb) with a traverse (“X”) axis of 4000 to 5000 mm and two-stage, telescoping vertical (“Z”) axis of 2500 to 3000 mm. The movable kick beam, with an unusual “negative” kick action, has a “Y” reach of 1800 mm. Servo A/C wrist is optional. Compared with previous Yushin large robots, like the RBII-2500S, the new model boasts 17% shorter takeout times and 10% faster overall dry cycles.

Engel introduced viper linear robots with longer strokes and other enhancements (see September show preview).

Wittmann Battenfeld brought out its new Sonic line of robots said to be 60% to 70% faster than its WX series. They have bigger motors with higher torque and 4X greater acceleration than standard models, as well as an aluminum vertical arm that is 15-30% stiffer than on previous units. Three models—Sonic 131, 142 and 143—are suited to presses up to 500 m.t. Payload capacities are 3 to 7 kg (6.6 to 15.4 lb). Custom models can be built with up to 10-kg (22-lb) payload. The initial three models have acceleration from 40 to 65 m/sec2 (the upper end is >6.5 G) and max. speeds of 5.5 to 7.5 m/sec. To accommodate these physical capabilities, the R9 Teachbox control has an internal cycle time of 4 millisec (vs. common values >20 millisec, Wittmann says), which allows for extremely fast response to change of signal status, such as Mold Open.

Speed is the key to two lines of robots from Star Automation, introduced in mid-2018. Aimed at packaging, IML, and other fast-cycle jobs, the ZXW-VI series comes in two models:

• ZXW-1000VI for presses of 150 to 350 m.t., with takeout time of 0.48 sec and full dry cycle of 2.6 sec;

• ZXW-1600VI for presses of 350 to 850 m.t., with 0.83-sec takeout time and 3.8-sec dry cycle.

All axes on these models have double prismatic bearing guides and special bearings to allow precise positioning to 0.1 mm. The vertical arm is telescoping.

Even newer and even faster is the first of the ZPX series, the ZPX-1000, for presses of 150 to 350 m.t., with 0.35-sec takeout time and 2.4-sec full dry cycle. It boasts new, lighter arm profiles, carbon-fiber vertical arm, and more powerful servomotors than on the ZXW line.

In six-axis articulated robots, Kuka presented the KR Quantec 2 series, with higher speed and 10% smaller dimensions, fast deliveries, and reduced total cost of ownership, thanks to optimized maintenance, 50% fewer main components, and fewer spare parts. They come in rated payload capacities of 120 to 210 kg (264 to 462 lb) and max. reach from 2701 to 3100 mm. They are also billed as the world’s first industrial robots to feature digital plug-in motion modes—software add-ons for these operating modes:

• Path Mode for highest precision;

• Dynamic Mode for highest speed, giving around 10% faster cycles;

• Performance Mode for standard operations (around 98% of applications).

Later this year, Sepro plans to bring out its more affordable Success Line X series with two-axis servo wrist, designed to “make five-axis robots standard for injection molding.”

Lower-Cost Automation

As noted in November’s Keeping Up section, Wittmann Battenfeld added two new models to its Primus line of economical servo robots—larger Primus 48/48T models for presses up to 900 m.t., and a telescoping-arm Primus 16T at the smaller end.

Sepro announced plans to bring out a prototype of a more affordable line of five-axis servo linear robots, called Success Line X, by the third quarter of this year. These will be based on a thorough redesign (now underway) of Sepro’s best seller, the three-axis Success Line, to which will be added a two-axis servo wrist from Yaskawa Motoman, one of Sepro’s partners for six-axis articulated robots. With Success Line X, Sepro aims to “make five-axis robots standard for injection molding,” according to company officials. Cartesian robots will thereby be enabled to take over more jobs from six-axis robots, giving advantages in speed and lower cost.

Success Line X robots will offer added flexibility for quick mold changes, secondary operations and other complex applications. Unlike a simple three-axis robot with a pneumatic wrist, the servo wrist on the upcoming models has sensors that tell the robot exactly where the wrist and gripper are positioned, facilitating more complex motions. Sepro says it also becomes possible to use simpler end-of-arm tooling (EOAT) because the servo wrist compensates more easily for minor misalignments. The company also plans to roll out a redesigned and affordable five-axis Strong Line X of large robots in 2021.

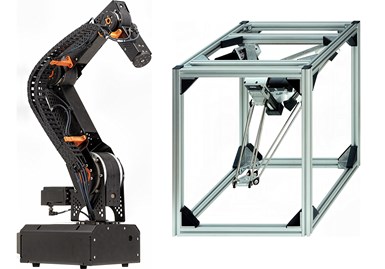

“Low-cost automation” is a new program from Igus that includes the four- or five-axis Robolink articulated robot (left) and drylin delta or spider robot (right).

Igus, the German supplier of plastic components for moving components of machinery, has launched a program of “low-cost automation.” Shown at K was the brand-new robolink RL-DC jointed-arm servo robot with four or five axes. This compact device was also shown at the Boy Machines booth, where it fit easily inside a Boy 35 E VV vertical press. Designed for simple pick-and-place applications, its price starts around 7000 Euros. Also available are drylin DLE-DR delta (“spider”) robots for high-speed pick-and-place jobs. Powered by electric stepper motors, this three-axis model handles up to 5 kg (11 lb) and makes up to 30 picks/min. It can be assembled from a kit. Price with controls starts a little under 5000 €.

Nissei molded PLA champagne flutes in two parts on two presses. Two top-entry robots (top) delivered the parts to a Kawasaki dual-arm DuAro SCARA-type cobot that assembled the flutes (bottom).

Cobots Proliferate

Collaborative robots (cobots) are a growing trend in plastics processing, and they were evident throughout the show in Düsseldorf. Although this report focuses on injection molding, cobots also played a role in blow molding at the show—such as a Universal Robots model housed within a machine molding jerrycans (see last month’s report).

As reported in December’s Starting Up section, Germany’s Hahn Group has re-established Rethink Robotics as a new subsidiary and has upgraded the quality, durability and payload capacity of its Sawyer one-armed cobot in a new Sawyer Black edition. A heavier-duty model is planned.

Sepro’s exhibit included two demonstrations of its new alliance with Universal Robots, a leading cobot supplier. And Boy Machines presented an encore demonstration from previous shows, in which a cobot served drinks in freshly molded mugs. This year’s exhibit featured a Kuka seven-axis cobot serving coffee (at K 2016, a UR cobot served beer).

As reported in last month’s review of K Show injection molding news, Nissei operated a cell that molded bases and cups of champagne flutes from clear PLA bioresin. The cell used two injection presses and two Yushin top-entry robots to demold the parts and bring them to an assembly station. There, a dual-arm SCARA-type cobot from Kawasaki Robotics assembled the two parts and placed finished flutes on a conveyor. The Kawasaki duAro operates collaboratively (in the presence of humans) with the aid of a collision-detection feature and a safety function that slows down its motion when a person enters its working space.

Muller Technology Colorado (formerly CBW Automation) is working with Omron’s cobots to develop a system that can pick and place IML packaging (top) and inspect it with an integral camera (bottom).

Muller Technology Colorado Inc.—the new name of CBW Automation, which was recently acquired by Mold & Robotics Group of Switzerland (itself now renamed Muller Group)—discussed its “extensive product-development work in the area of collaborative robots for injection molded packaging.” Taras Konowal, sales director, said Muller is working with Omron’s six-axis articulated cobot equipped with an integrated camera and able to be moved from machine to machine. The first application reportedly will be lid packing in consort with a CBW stacker, of which there are 1500 in use.

Other Robot News

Additional news from Muller Technology Colorado is that the latest generation of its IML side-entry robot was redesigned to trim energy consumption by up to 40%. This was achieved by optimizing motor speeds and shortening air and vacuum lines by moving control of these utilities closer to the active functions they serve. Muller also is bringing to the U.S. sophisticated IML automation technology from its European operations. This equipment will be built in the U.S. to allow for faster deliveries.

Meanwhile, Boy showed off its expanding portfolio of automation solutions with a version of its three-axis parts remover expanded to four axes with a wrist.

Campetella Robotic Center of Italy (represented here by Hunter Automation & Robotics) operated a dedicated system with three robots for production of home-compostable coffee capsules (or pods) with IML. Using a Netstal Elion 1200-510 all-electric press and a four-cavity mold, a four-axis X-Series Mini-Modula side-entry robot inserted the labels and removed the finished capsules, placing them on a conveyor. A camera inspected the capsules. At the end of the conveyor, an X-Series SPIN1 SCARA robot picked up pairs of capsules and transferred them to another conveyor. Finally, an X-Series MC2-2H five-axis Cartesian top-entry model performed stacking and palletizing, using a new upstacker that can handle two to eight parts at a time. Total cycle time was 8 sec.

An interesting feature was the compostable material used in the capsules—PP mixed with 35% sunflower-seed hulls, called Golden Compound and produced by a German company of the same name. Natural foaming action of the plant fibers combats sink and yields a final density as low as 1.02 g/cm3.

As reported in our September K preview, Engel showed a new “multidynamic” function for its viper Cartesian robots, which adjusts speed according to the payload; a new Engel pic A sprue picker; new “compact safety cell”; and presented an impressively complex composite overmolding cell with two ovens and three integrated six-axis robots to preheat and load three different organosheet blanks.

Hekuma demonstrated its latest Hekutip automation cell for demolding, inspecting, cavity separation and packing of medical pipette tips (see September Keeping Up).

Sepro, as noted above, is overhauling its popular Success line of Cartesian robots, with the results available for delivery in the second quarter. The new generation will have sleek styling and features like an extended strip stroke, which can potentially allow a robot of a given size to service a press of larger tonnage than before. Sepro also has returned to cam-follower bearings for linear motions of the new robots. Patented years ago by Sepro to handle heavy payloads and long strokes on large robots, they are now standard on all models. These bearings are said to provide more even weight distribution and smoother operation than linear bearings and to be also more reliable, durable and tolerant of dust and other contaminants.

Also new is Sepro’s Visual Production Dashboard that captures data from the robot and the whole cell to help improve plant efficiency. Sepro’s Visual robot control can aggregate the data produced by the whole cell—injection press and peripherals—with its own measurements to calculate the cell’s OEE in real time. In that sense, Sepro says, the robot acts like a “smart sensor.” (At NPE2018, Yushin likewise proposed using the robot as an overall cell production monitor.)

As reported in November Keeping Up, Hahn’s Waldorf Technik subsidiary demonstrated the latest version of its Vario TIP system for demolding and cavity sorting of syringe barrels. Waldorf also showed off Hahn’s new EVE Suite of digital services, such as remote monitoring and maintenance support.

Meanwhile, Hahn’s Wemo robot subsidiary displayed new WIPS 4.0 control software and a new handheld pendant with 10-in. touchscreen that takes gesture commands, as well as the new xPacker palletizing robot (also reported in November). Wemo also showed an approach adopted by several automation suppliers to free up a demolding robot for faster cycles. The approach is to hand off the parts to a second robot at the same vertical level as they were demolded; while the first robot returns to the mold, the second robot lowers the parts to a table or conveyor. The first robot is thereby freed from performing the vertical stroke in two directions.

Wittmann Battenfeld introduced a complete redesign with the WX138 robot for presses of 150 to 300 m.t. (12 kg/26.4 lb payload). It has a fixed kick stroke to the front and replaces the model W828 with kick-axis forward design, as well as the W821 and W831 with moving kick axis. Other new features are the greatly increased rigidity of the vertical axis and concealing the drive unit inside the profiles of the main (“Z”) and demolding (“X”) axes, eliminating pinch points (see November Keeping Up for more details). It comes with the new R9-WLAN Teachbox pendant, whose cradle doubles as a charging station. The pendant can be used on its own or together with the R9 embedded in the Wittmann Battenfeld machine’s controller; one R9 can even service several presses.

Kuka is testing a new, intuitive, icon-based programming method for its six-axis robots. Called Kuka.IconProg, it’s designed as a simpler alternative to conventional KRL programming language. With IconProg, the user selects the building blocks of an operating program from a library of more than 600 functions and assembles them in a graphical sequence diagram.

In addition, Kuka recently acquired another company that brings simulation and augmented reality to planning equipment layout (collision detection and distance check) and offline robot programming. It’s called Kuka.Sim Pro.

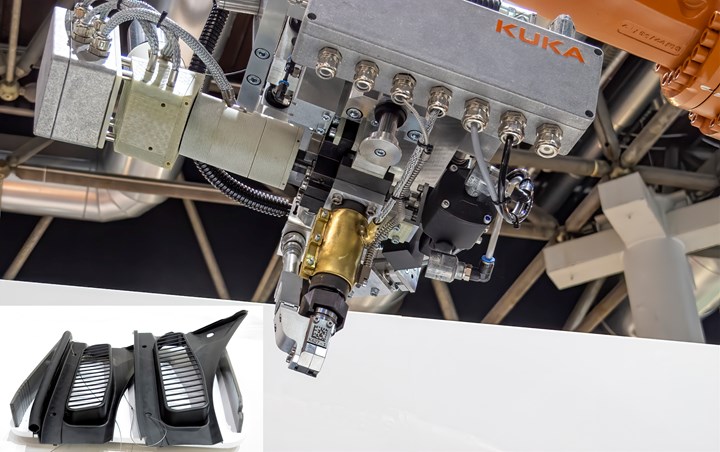

Kuka introduced a new extrusion head for its six-axis robots, which can deposit gaskets directly onto molded parts (inset, left).

Also new from Kuka is an extrusion head that can be mounted on a robot to apply a thermoplastic gasket to a molded part.

Staübli showed off new a quick-change device for six-axis EOAT (top) and a new mold-maintenance cart for its automated QMC system (bottom).

Staübli has a new tool changer for six-axis robots. It’s a standard, modular unit that is configurable, rather than custom, enabling shorter lead times. Staübli says it’s the only one on the market now with ISO level D, category 3 mechanical safety, sought by the automotive industry. The pneumatic system cannot unlock the tool when it’s mounted on the robot—only when it’s on the tool-changing stand.

EOAT components

Sepro aims to make EOAT component sourcing simpler through collaboration with Gimatic and AGS. Sepro’s new “My Gripper” system provides one-stop access to over 700 components for EOAT through a 66-page catalog.

Star is offering new online purchasing of its eins gripper components through its website.

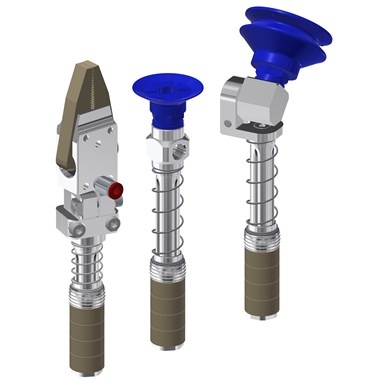

AGS of Germany, represented here by Schunk and in a new collaboration with Sepro, introduced spring-loaded grippers that are compliant with minor positional variances. Made of lightweight aluminum, they also have an anti-rotation feature.

And AGS (which is represented here by Schunk Intec In., Morrisville, N.C.) has several new EOAT components in its catalog:

• Spring-loaded gripper arms that can compensate for minor variations. These are all-aluminum for very light weight, and have coated sliding surfaces and an anti-rotation device.

• Gripper ground plates with standard ISO flange hole patterns. These eliminate the need to adapt ground plates to the robot flange.

• Kit system, developed in collaboration with Schunk, to combine AGS’s PreciGrip modular gripper systems and the full range of common Schunk grippers.

• Centering locking unit for grippers that enter an injection mold. The unit stays locked in case of pressure drop.

• Custom 3D-printed grippers based on the user’s CAD data. These allows more functions to be combined in one part. Printed components can be painted, smoothed, PUR-coated, and flocked.

QMC and AGV

Staübli added an optional mold-maintenance station to its automated quick-mold-change system. This mobile, cart-mounted system can open a mold and tilt a mold half to make it easier to work on, all without use of a crane. The new modular design handles molds weighing 10 to 60 tons, big enough for presses over 1500 tons. This pre-engineered solution is offers lower cost and shorter lead time than previous units designed from scratch for each customer.

Kuka’s new model KMP1500 WLAN-guided AGV can carry molds or other loads up to 3300 lb.

Kuka expanded the range of its automated guided vehicles (AGVs) suitable for transporting molds or large workpieces (such as a whole car body). The new model KMP1500 (Kuka Mobile Platform) can carry 1500 kg (3300 lb). It’s guided by WLAN and an onboard scanner “sees” obstacles, which cause the cart to stop and then try to go around. Every wheel on the cart is driven independently.