Welcome to Thomas Insights — every day, we publish the latest news and analysis to keep our readers up to date on what’s happening in industry. Sign up here to get the day’s top stories delivered straight to your inbox.

In a recent episode of the Thomas Industry Update Podcast, Thomas CEO and President Tony Uphoff interviewed Rockwell Automation‘s VP of Digital Transformation Keith Higgins. During the episode, Higgins breaks down digital transformation and how manufacturers are making the transition to Industry 4.0 technologies, despite challenges and reluctance still common among some executive leadership.

Higgins explains, however, that the transformation is not as challenging as it sounds. It starts, he says, by honing in on what matters at your facility: What processes can you improve by utilizing Industry 4.0 technology?

Here’s a four-step guide to making digital transformation approachable for your industrial business and how to get started.

1. Get the Ball Rolling

Although Higgins prefers to focus on helping clients to improve in order to reach their goals rather than highlighting possible mistakes during the adoption process, he does note that he does he often hears business leaders say, “‘I wish I had gotten started a little bit sooner.'”

Industry adoption is no longer optional, he points out. At this point, Higgins explains, it’s a necessary step to keeping up with competition in the industry. Research has supported this strategy, especially in light of the demand for digital operations amid COVID-19. According to a recent study by the MPI Group, respondents saw Industry 4.0 as highly impactful in the future – 90% said that over the next 5 years it will have “significant” or “some” impact, and only 9% downplayed the impact.

“Early movers of digital transformation have shown separation in business performance,” Higgins explains. “People are realizing, ‘Hey, I better get going because my competitors are.’ So it’s more of a competitive imperative now than maybe fear and opportunity. It’s becoming much more mainstream today.”

2. Look at Your Data

Now that you’ve established that it’s time to start your adoption journey, it can be challenging to gauge where to start digitizing your operations. MPI indicates that nearly half of manufacturers (47%) have strategies implemented to apply Industry 4.0 to processes, but only 37% have done so for their products.

Higgins urges industrial businesses to understand that not everything needs to be accomplished at once, and the best place to look for a starting point is in your data.

One of the most common questions he hears, Higgins says, is “‘how do I compare what’s happening right now with what’s happened historically?'”

To start comparing, Higgins advises, “Look for anomalies, looks for patterns. Look for things that are different and use that [information] to generate insights that could help improve operations very quickly.”

It’s important to understand that Industry 4.0 adoption will look a little different for every industrial business, depending on where improvements are needed. However, MPI’s Industry 4.0 Drives Agility and Productivity in Manufacturing study indicates that adoption in these areas has provided the most value for manufacturers so far.

- Financial value: Supply-chain activities (50%)

- Operational value: Operations (63%)

- Brand value: Sales and marketing (46%)

3. Create Value-added Assets

MPI says that 49% of manufacturers struggle with beginning their digital transformation because they can’t identify the opportunities/benefits the transition will provide. While part of digital transformation lies in adopting new, high-tech machinery for efficiency, the transition has also brought with it a wave of “as-a-service” opportunities to create new revenue streams.

According to Higgins, digital transformation can be easier for manufacturers who look at it as a way to make Industry 4.0 a value-add for the business.

“We’re living in a subscription economy, so everybody wants to get to [the ‘as a service’] model,” he explains. “So for our customers that make everything from HVAC systems to you-name-it, the ability to start to sell that either as a service or with a value-added service like predictive maintenance is a big, new revenue stream. It’s a way for people that make equipment to really differentiate themselves and to create value-added services and to create new revenue streams.”

4. Integrate IT/OT Operations

According to MPI, not all manufacturers are in agreement regarding the technologies that comprise Industry 4.0. They agree most commonly on factory automation (62%) and artificial intelligence (62%), and least commonly on fog, edge, and cloud computing (22%).

However, in the words of Higgins, “edge is the new cloud” and manufacturers need to be taking advantage of all of these opportunities, albeit some at the later stages of digital transformation.

“The industrial internet of things, to me, really is what’s happening at the edge now — what’s happening where OT meets IT,” he says. “[But] I don’t mean that as not cloud-centric. Cloud is a very important part of digital transformation. But the cloud has kind of been figured out by a few big players, and that has not happened at the edge. The Wild West is now who will be the big winners at the edge.”

So what is edge, and how can industrial businesses get ahead?

Just like “IIoT” and “cloud,” edge is another buzzword in the market. However, in this context, the term edge refers to the literal geographic distribution of your data. Edge computing is then done near or at the source of the data, instead of relying on the cloud to draw from data centers to pull your information. In the words of The Verge, “It doesn’t mean the cloud will disappear. It means the cloud is coming to you.”

Higgins cites lower latency and less security infrastructure as some of edge’s big advantages and anticipates it becoming the next big tech on the market.

“When you take OT data, you need the context. The temperature of a conference room is not enough. You need to know what time of day with it, how many people were in the room, were there any air conditioners in use,” he explains. “So in a common data model that can be automatically ingested by the IT world, whether it’s IoT gateways or platforms or cloud companies, etc., that’s one of the biggest areas of innovation right now is in intellectual property being developed to really automate OT data with context and be ingested by IT systems.”

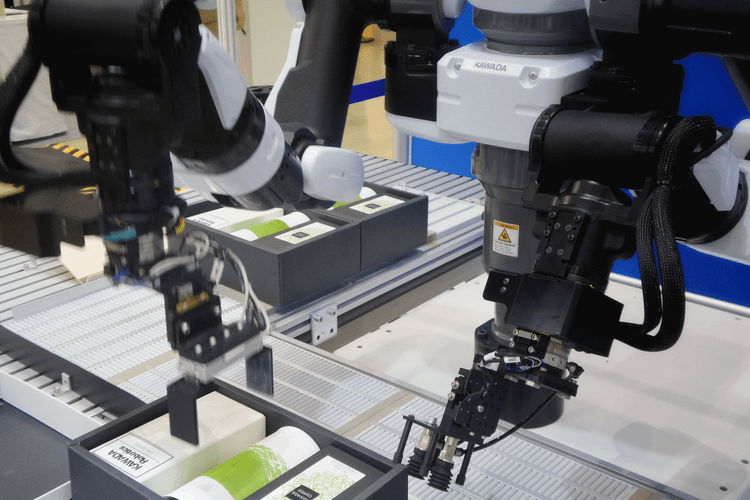

Image Credit: Photo by Photos Hobby on Unsplash